the drug solution has by now been manufactured and packaged. In the course of an aseptic fill finish procedure, packaging parts along with the drug products are sterilized prior to getting combined under sterile disorders.

From the dynamic realm of pharmaceutical manufacturing, liquid bottle filling devices stand as the vanguards of efficiency and accuracy. These cutting-edge automatic techniques have sparked a revolution from the packaging of pharmaceutical liquids, propelling productivity even though upholding uncompromising quality Regulate.

A essential assessment with the groupings as well as their contents showed that we didn't have a certain document focused on the technological innovation of sterile filling. When there were files addressing aseptic tactics and sterility assurance controls, there was nothing at all specific to your devices and process of receiving a product right into a sealed container–closure technique. The filling course of action move has numerous demands to get met, such as:

All instruments needs to be calibrated just before any significant operational qualification can be executed. Prepared calibration treatments really should specify the techniques to be used for every instrument. Recalibration needs to be completed following any maintenance, and all records managed. New equipment specs really should state prerequisites for:

Why is lyophilization made use of when manufacturing parenteral prescription drugs? As the amount of elaborate drug products which pose security problems turn out to be extra popular and also a liquid dosage type is not possible, drug developers transform to sterile lyophilization.

Employing a brainstorming system and in cooperation with a danger management specialist, all click here attainable risks related with each and every step are discovered.

BFS packaging signifies a significant progression during the aseptic packaging of pharmaceutical and Health care solutions.

A gaggle of scientists, consisting of the pharmaceutical marketplace expert and a tutorial instructor, have picked a sterile infusion in the shape of a one hundred mL glass bottle product or service and chose to carry out an extensive overview of The entire manufacturing strategy of the item daily life cycle as comprehensive in Determine 1. The generation operation of the pharmaceutical merchandise has a couple of distinct processing stages. Every single stage is comprised of numerous lesser process methods. In general, all pharmaceutical manufacturing operations start with procurement and provide chain administration, then proceed to storing and managing with the raw substances along with the packaging elements, then procedures of production as raw products linked operations which include dispensing, formulation, filling, inspection, labeling, packing, palletizing and ending with storing and distributing of the concluded product.

These suites have strains capable of filling injectable goods in vials/stoppers and preservative-absolutely free nasal sprays (vial/snap-on nasal pumps). Our filling traces make the most of RABS know-how and are validated to aid an array of packaging factors. Just about every line can aid possibly aseptic sterile processing or terminal sterilization and both of those strains are presently manufacturing FDA accepted business products and solutions, As well as get more info various development systems with the clinical demo amount.

Publisher’s Observe: MDPI stays neutral with regards to jurisdictional claims in revealed maps and institutional affiliations.

The number of containers utilized for media fills needs to be adequate to enable a valid evaluation. For modest batches the volume of containers for media fills should not less than equivalent sizing of product or service batch.

Creation delays. Stringent restrictions governing aseptic manufacturing mean that there will be prolonged delays should really a product be exposed to microbial contamination.

Tracing its origins presents insight into how this innovation has developed to satisfy stringent sterility necessities.

Enough time for an entire-scale operate of your respective beverage will arrive. But a small-scale run would be the best expense at this time within your brand name's advancement.

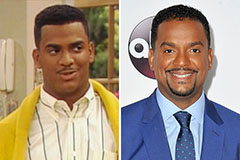

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!